Currently new versions are undergoing test to ASTM D 113/117 that will combine anticorrosive properties in addition to the passive fire protection capability. Furthermore to enhance performance envelope bolt caps are to be earthquake testing in QTR 3 2021.

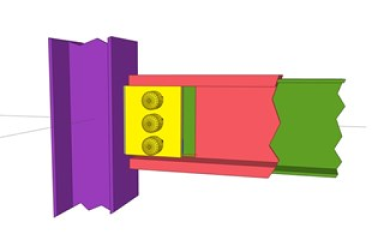

The hard wearing and versatile technology of the bolt cap has allowed a new application to be developed.

Bolt caps have been used in mining application to provide bolted connections with protection against corrosion and erosion in a very harsh environment.